Nitrogen Rejection

Nitrogen rejection allows for the removal of nitrogen from feed gas to produce a treated residue gas stream with minimal nitrogen content and an improved heating value. Generally, the suitable nitrogen rejection process is highly dependent upon the nitrogen content of the feed gas as well as the other constituents of the feed gas.

Zechstein offers proven pressure swing adsorption based solutions involving a macroporous, robust styrenic polymer resin bead as the adsorption medium. This solution has been in use for hydrocarbon removal from water and air streams as well as for VOC removal for over twenty years.

Our NRU’s can be designed for flowrates as low as 25 m3(n)/day to over 1.500.000 m3(n)/day with pressures ranging from 9 to 90 bar(g). In many cases, we recover in excess of 99% of the hydrocarbons present in the gas stream in a single pass.

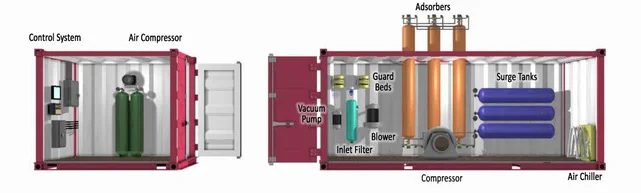

Our units are modular and are housed in standard shipping containers allowing for easy installation and removal but also scalability to follow field production levels.

The nature of the adsorbent and the modular design allow for a very high turndown, approaching 100% of design throughput and, with built-in redundancy, uptime can be close to 100% as well.

A Zechstein Nitrogen Rejection Unit provides an ideal solution to recover high calorific value natural gas from low or very low calorific value natural gas under a wide variety of gas composition and process conditions. Our solution offers fields that are uneconomic under existing nitrogen rejection options an opportunity for development.

The recovery of helium and the production of CNG or LNG can also be achieved with the addition of further third party processes.